Jaguar Land Rover are again taking innovative steps to tackle the issue of plastic waste.

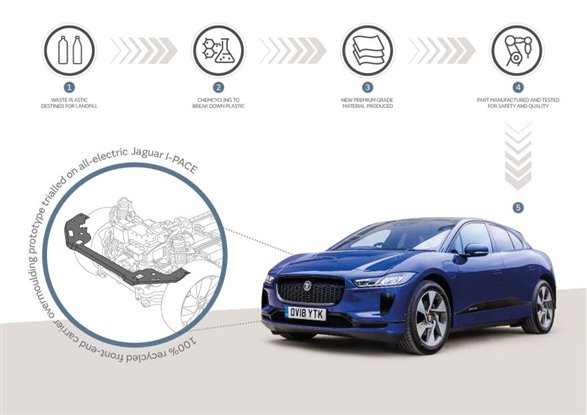

They have teamed up with chemicals giant BASF to pilot a project called ChemCycling, a procedure which takes domestic plastic waste destined for landfill and instead use it to produce high-quality material for use on new cars.

Stringent safety and quality standards impact on the amount of plastic waste currently suitable for recycling but, with 12 million tonnes of waste predicted globally by the middle of the century, experts are looking at new ways to increase recycling capability. ChemCycling uses a thermochemical process to reduce plastic waste down to a pyrolysis oil, which is then used to produce plastic for next-generation dashboards and exterior surfaces. The manufacturer is currently trialling the material on the Jaguar I-PACE’s front-end carrier overmoulding to verify it meets the same stringent safety requirements of the existing original part, and should the tests be successful Jaguar Land Rover plans to use the material for other components across its range.

Jaguar Land Rover has already declared war on plastic waste, and with the removal 187 football pitches worth of plastic from its production and business premises the manufacturer has already met its Zero Waste to Landfill target for its UK operations a full year early. The new development is the latest innovation from the manufacturer, with Range Rover Velar and Evoque models already available with a durable seat material produced by blending wool with a faux suedecloth made from 53 recycled plastic bottles.

Click here to sign up for our monthly newsletter

Popular news stories

|

|

|

|

|||

|

|

||||||

Related used car searches

Search used Jaguar

Search used Land Rover